specification description

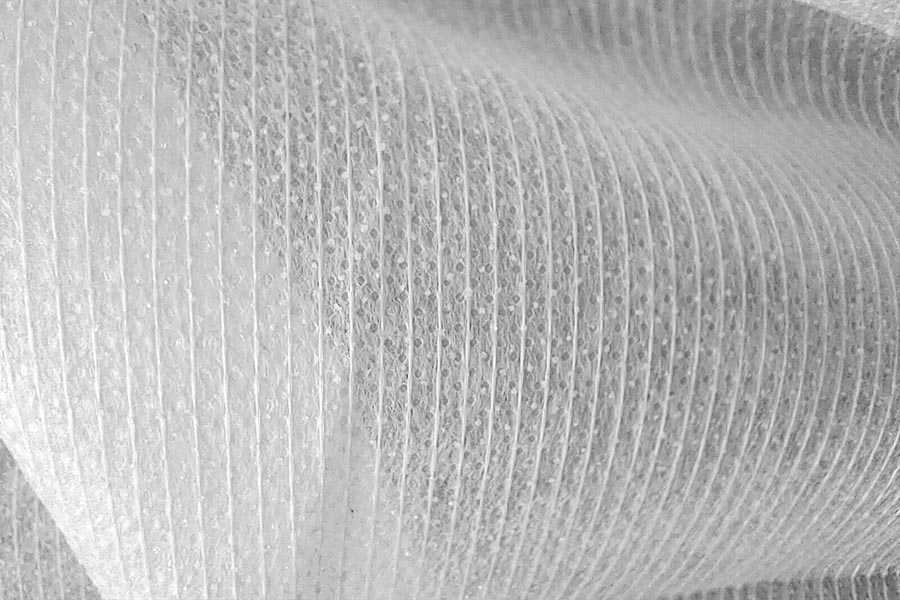

Comparing D7025 and C7018, they have the same production process of base non-woven fabric, but the coating process is different. Due to the maturity of the process technology, better adhesion strength, better washing water resistance, and continuous reduction in cost, the double dot coating process is more and more widely used, which is welcomed by clothing designers and used in all kinds of clothing.

Huzhou Joybay as a professional interlining manufacturers, has the complete production process for nonwoven interlining, include base nonwoven fabric making, thermal bonding and glue coating, which can ensure stable quality of each production process and control the cost well, It is an honor that you would like to get to know us and hope that we can build further trust and connections.

The following suggested fusing condition are for reference only, we recommend testing the products before using them in your project.

fusing condition:

| Coating Glue | Bonding Machine Type | Bonding Temperature | Bonding Pressure | Bonding Time |

| PA coating | Roller bonding machine | 120-135 | 1.5-2.5kg/cm2 | 12-15S |

| PA coating | Flat bonding machine | 120-135 | 0.8-1.5kg/cm2 | 12-15S |

| PES coating | Roller bonding machine | 120-135 | 1.5-2.5kg/cm2 | 12-15S |

| PES coating | Flat bonding machine | 120-135 | 0.8-1.5kg/cm2 | 12-15S |

Application areas

Very suitable for all kinds of light and thin clothing, both woven and knitted clothing are suitable.

For the fusing of small parts in blouses and dresses and front parts of elastic jackets, waist band of trousers. Suitable for lightweight, transparent and sensitive fabrics.

The related products you may interested

Contact Us

If you are interested in this interlining, or need customization, or have any questions about coating, fabric matching, fusing temperature, pressure, time, and washing condition, please do not hesitate to contact us.